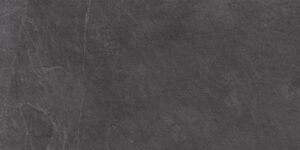

Black Slate Italian Porcelain Paving – 1000 x 500 x 20mm

£39.75 (ex. VAT)

- Description

- Additional information

- Product Guidance

- Colour Variations

- FAQs

- Additional Information

- Specifications

Description

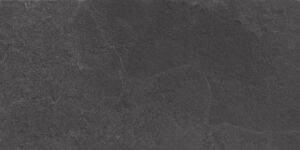

Black slate Italian porcelain paving offers a beautiful consistent colour palette of blacks and charcoal tones with perfectly captured surface finish of natural slate, with it’s flat but textured surface and straight edges, Black Slate Italian porcelain offer all the atheistic benefits of natural slate but with the hardwearing low maintenance properties of high quality Italian product.

Black Slate Porcelain is available in 1000 x 500 x 20mm (Nominal Size)

Dimensional tolerance + or – 2% (max 5mm) in both width and length.

If you’re interested in find out more about our range of beautiful Italian Porcelain Paving slabs or need to check the stock levels of our Porcelain Paving near you, please contact our Portsmouth, Poole, Winchester or Tadley branches for more details.

Porcelain is becoming increasingly popular, with many benefits it’s not hard to understand why.

- Subtle colour variations and consistent surface texture

- Real stone looks, only possible with the high end Italian production techniques

- Durable with very low moisture penetration, reducing moss and algae build up.

- Virtually maintenance free, mop up those spillages without the worry of staining your beautiful paving, simply jet wash when it becomes dirty.

- Resilient to weather and temperature changes, it will not fade in the sun and will not be affected by freezing during the colder months.

- Non slip with a lightly textured surface.

- Highly resistant to scratches and other damage.

- No additional specialist equipment need to lay porcelain just a good quality Porcelain diamond blade.

WHY EUROPEAN PORCELAIN ?

Italian porcelain is manufactured to the highest quality standards, they have a more realistic surface appearance mimicking natural stone perfectly, whilst still offering reduced maintenance, increased slip resistance and its superior manufacture that makes it easier to cut than all other porcelain products on the market.

We use the latest technologies in all our production plants, all of which are Sacmi machinery (sacmi is the number one in world for production line machinery and technology)

We source the finest raw materials from specific quarries from around the world to give best final result in quality of finish, for better durability meaning greater longevity of use, greater consistency from batch to batch as well as the latest high-definition inkjet printers for more defined realistic graphic design.

Our printers use minimum tri-colour heads to enable a wider spectrum of graphic variance, double most other products available in the UK, and refined attention detail for more realistic results. We have invested in longer than average Kilns for our production, this enabling us to manage closer and better the overall result of each product, this is achieved by gradually firing the tile over a longer period between temperatures of 1000 to 1300 degrees C, building the temperature up gradually and then a longer cooling down process meaning thus resulting in less stress on the product, meaning no bowing and less brittle than our competitors.

The production processes we use are above the industry norm, this helps us ensure our products have greater density than the average product in the market, meaning greater strength and less subject to wear under heavy foot traffic environments

For more information about different Porcelain Paving types please follow the link below to our news article on the subject:

Understanding Porcelain Paving

Trade discounts available please contact your local branch for details (company registration number required)

There will always be colour variations between batches, ensure you order enough to complete your project from one batch, never mix batches, allowing additional material for cuts and wastage.

Additional information

| Weight | 50 kg |

|---|

There will always be colour variations between batches, ensure you order enough to complete your project from one batch, never mix batches, allowing additional material for cuts and wastage.

Always keep a record of the batch code of the porcelain you have collected or had delivered, just in case future stock is required. The batch code is printed on the side of packaging boxes covering the porcelain paving products.

Please note the shade of the final product could differ slightly compared to the sample you may receive due to batch variation.We recommend that all customers read our product selection, maintenance & installation guides before purchasing, please follow one of the links below:

PORCELAIN PAVING INSTALLATION GUIDE

When installing Porcelain paving please ensure that you use Pro-prime to help bond the slabs to the sub-base, this product is available at all Natural Stone and Timber branches.

Do Porcelain Paving Slabs Fade?

As a rule no porcelain paving slabs do not fade, but over very long periods of time in sunny areas and with considerable weathering you could expect to see some slight changes to the appearance of the surface of the slabs.

Can You Cut Porcelain Paving?

Yes, our Porcelain Paving can be cut easily, but you will require a very good quality diamond blade made especially for 20mm Porcelain paving slabs. European & Italian Porcelain paving cuts a lot better than India porcelain due to the improved production processes making them less brittle and prone to chipping, but due to its increased density, it can take longer.

Can You Seal Porcelain Paving?

Yes, it can be advisable to seal Porcelain Paving. This will further reduce porosity and keep any maintenance to an absolute minimum, but it is not essential and is basically a personal choice.

Does Porcelain Paving Stain?

It is possible to stain Porcelain Paving but it’s very difficult due to its very low porosity. Porcelain paving can be sealed to further help prevent staining in areas prone to spillages.

Does Porcelain Paving Scratch Easily?

No Porcelain Paving does not scratch easily, it is an extremely dense material that is very hard to damage once installed. If the surface of Porcelain is damaged or scratch it is not possible to repair, so we would also recommend keeping a couple of extra slabs hidden in your garden just in case of future problems.

Are Porcelain Paving Slabs Low Maintenance?

Yes, Porcelain slabs are incredibly low maintenance, they have very low porosity of 0.5% minimising dirt penetration into the surface meaning in normal situations no more than a general clean will ever be necessary.

Is Porcelain Paving Any Good?

Yes we believe we offer the best possible quality Porcelain paving that will far exceed any domestic requirements and will, if correctly installed, last for decades without requiring anything but general cleaning and maintenance.

Is Porcelain Paving Hard To Lay?

Porcelain paving is a very hard and precisely manufactured products, so some additional knowledge is needed to handle this material correctly, but any well experienced landscape contractor with the correct tools will not have any problems installing any of our products.

Are Porcelain Paving Slabs Expensive?

Porcelain paving has become very competitively priced within the UK market, with a high quality Polish or Italian Porcelain product priced competitively against inferior imported porcelain and natural stone products. We would always recommend installing the best possible Porcelain Paving slabs you can afford as the actual costs of the paving materials itself, is only a fraction of the overall installation cost, and is the thing you will be left looking at for many years to come.

Are Porcelain Paving Slabs Slippery?

All paving that is used within the UK must be R11 slip rated to meet the current British standard for paving materials. All our Porcelain Paving products have been tested and meet or exceed these standards. Technical Data Sheets are available to view for all porcelain paving products, just follow the link on the product pages.

Specifications for Black Slate Italian Porcelain Paving - 1000 x 500 x 20mm

| Material | Porcelain |

| Country of origin | Italy |

| Top finish | Non Slip |

| Shape | Rectangle |

| Effect | Slate Effect |

| Colour | Black Slate |

| Weight | 25kg per slabs |

| Slabs per square meter | 2 |

| Sealing | Not Necessary |

| Slip Resistance | R11 |

| Frost resistant | Yes |

| Maintenance | Easy |

| Suitable for | Patios, Step & Pathways |

| Can be tiled on | Walls and Floors |

| Estimated delivery | In Stock |